The Problem:

Catalysts are used throughout many industries and can be extremely expensive. In the petrochemical refining industry, many different catalysts are utilized, however, they each have substantial drawbacks. AlCl3 is used, but it requires expensive deacidification in the process. HF is used, but it is extremely volatile, corrosive, toxic, and overall undesirable. Lastly, zeolites are also used, and they are safer than both predecessors, however, they are much less efficient.

The Solution:

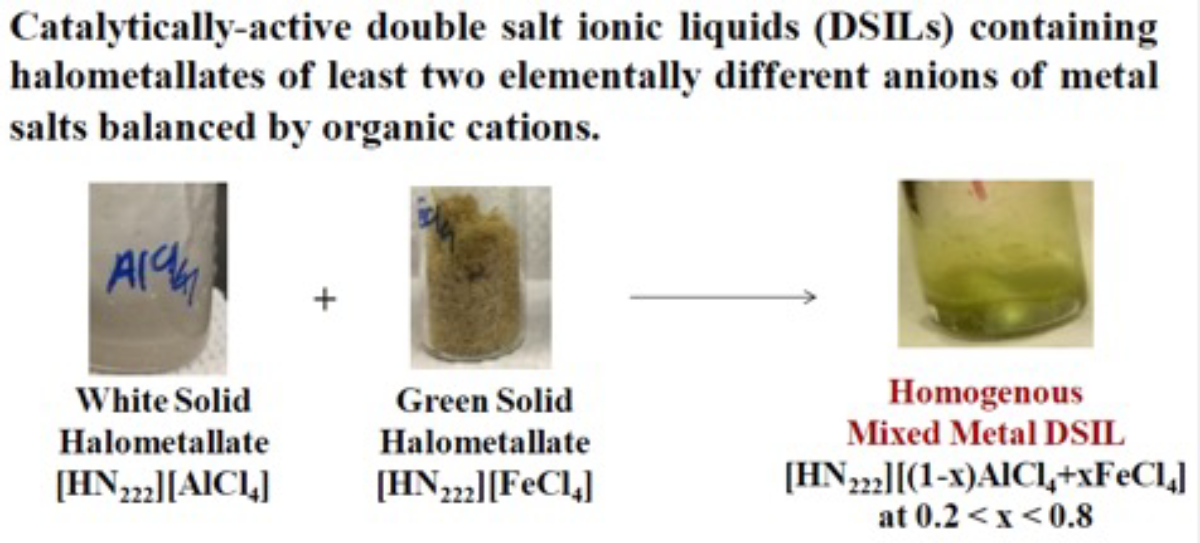

This technology involves new materials of matter based on mixed metallate double salt ionic liquids (DSILs). These new materials of matter liquids can be utilized for chemical transformations that require acidic catalysts (including the full range of Lewis acidity) or as a replacement of a mercury based catalyst in hydration reactions. Because the material of matter are liquids, the metallic ions can be combined in many ratios, allowing for the acidity to be finely tuned.

Benefits:

• Highly tunable, allowing for ultra-fine control over Lewis acidity.

• DSILs are typically non-volatile liquids and can act as replacements of currently used toxic or volatile systems.

• DSILs can form separate liquid phases with many common hydrocarbons, allowing them to act as heterogeneous liquid catalysts, combining the advantages of solid phase catalysts with the kinetics of homogeneous catalysts.

The University of Alabama Office for Innovation and Commercialization(OIC) is a non-profit corporation that is responsible for commercializing University of Alabama technologies and for supporting University research. At OIC, we seek parties that are interested in learning more about our technologies and commercialization opportunities, and we welcome any inquiries you may have.