The Problem:

Current nanorod materials on the market have relatively bad thermal stability, particularly with higher temperature applications. A high oxygen storage capacity (OSC) is hard to achieve and maintain at the 500 degrees Celsius threshold, yet CeO2 nanorods are only stable up to 450 degrees Celsius. It is apparent there is a temperature disconnect between the two necessary factors: nanorod stability and oxygen storage capacity.

The Solution:

This invention introduces aluminum oxide into the nanorod structure in order to increase thermal stability as well as improve reducibility. Additionally, the need for zirconium is eliminated with this process. These novel structurally stable nanorods can operate at and withstand higher temperature ranges.

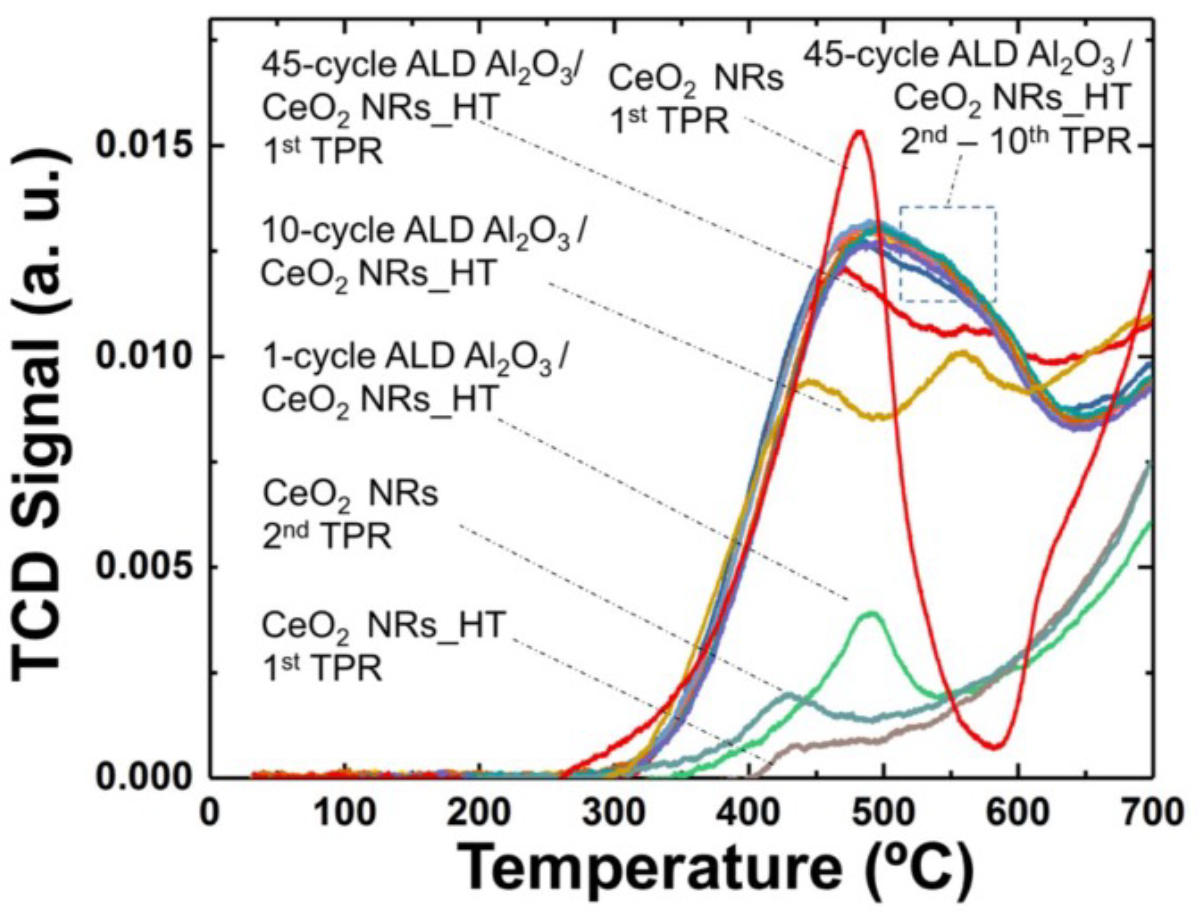

The Thermal Conductivity Detector for each composition is tested over temperature and graphed.

The Thermal Conductivity Detector for each composition is tested over temperature and graphed.

These results show that the aluminum oxide nanorod is thermally stable up to at least 700 degrees Celsius.

Benefits:

• The stable nanorods can be used as catalyst supports for a large range of reactions.

• Greatly increased stability at higher temperatures.

• Better reducibility than current nanorods.

The University of Alabama Office for Innovation and Commercialization(OIC) is a non-profit corporation that is responsible for commercializing University of Alabama technologies and for supporting University research. At OIC, we seek parties that are interested in learning more about our technologies and commercialization opportunities, and we welcome any inquiries you may have.